Unique style of cafe racer mod for this base model of Yamaha RX-Z. Looking good and nicely executed. via: Art of Speed Malaysia

Category: rx-z

Ady Sevens shared the link about this Yamaha RX-Z modified to motocross style as seen on Mudah.my. This kind of mod is very unusual since most RX-Z are modded lightly just to make it street legal but powerful and fast. This one in motocross style are equipped with monoshock rear suspension and the exposed front…

I love this SRZ 150. It have the same styling like the legendary Yamaha RX-Z 135 which has been a rider ‘super’bike for a very long time. This on, SRZ150, features an engine with 4-stroke 150cc displacement and single cylinder. It still looks good event though it is just a 4-stroker. It can be a…

Yamaha RX-Z is one of the most popular bike in Malaysia. It represent the perfect bike for anyone who like to have power, speed, style and freedom in the world of biking. Yamaha RX-Z have all the formula for an exciting biking experience and the same time maintains the price to be affordable for almost…

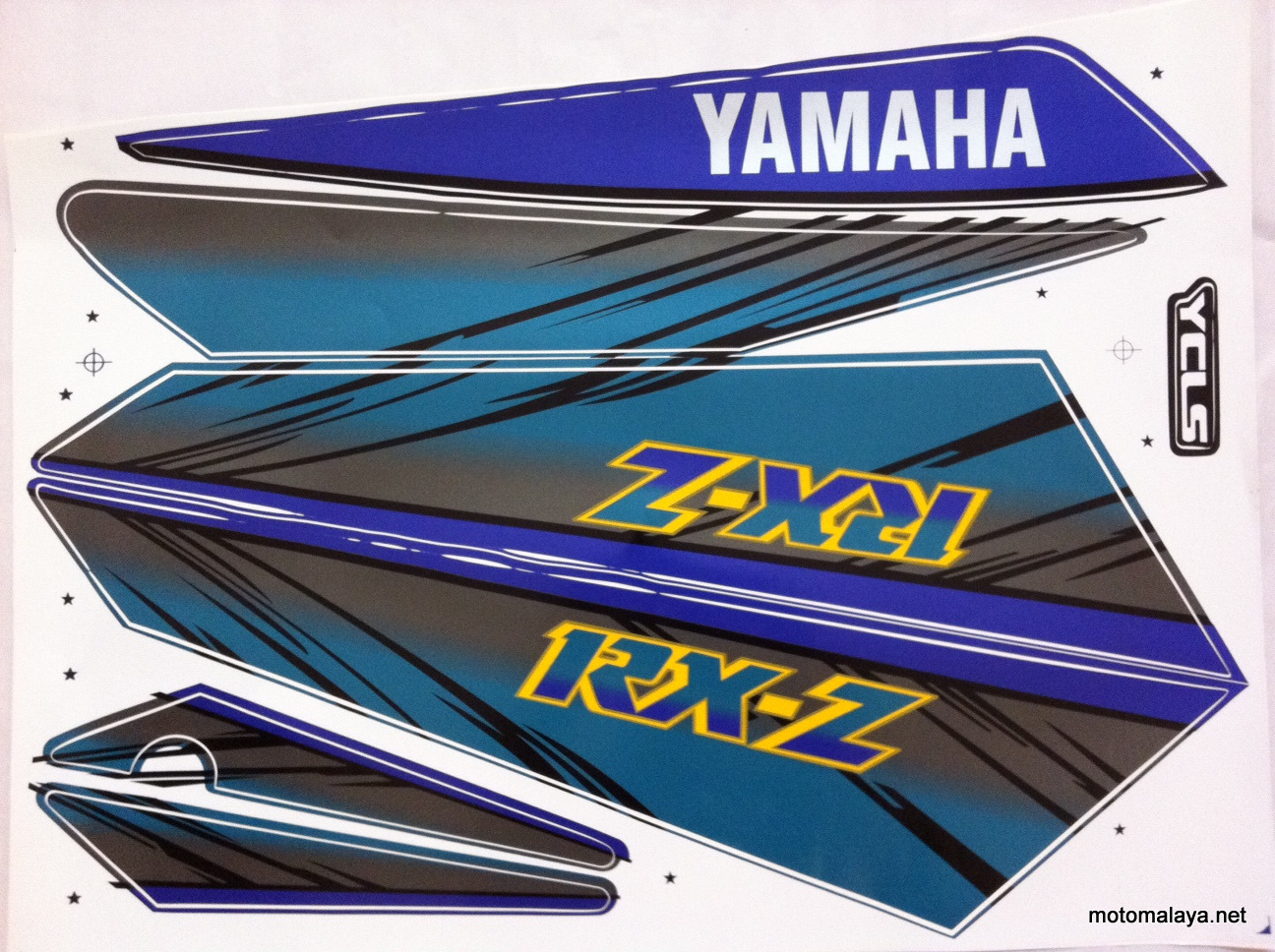

This is the same decals sticker that I have installed to my 1997 6-speed RX-Z. Looks normal. Not so mean and not so soft. Just perfect. I don’t know this sticker is originally for RX-Z in what year. So, I hope you can help by giving comment if you know. 2 more pictures after the…

Yamaha RX-Z Millenium This bike belongs to me.

1997 6-Speed RX-Z Restoration Project Do you still remember the picture above? It is about a Yamaha RX-Z bike that I bought for RM500+ that I’m going to restore sometime in May 2008. Now, the restoration has finished. Enjoy the picture below and look for the original look for the bike before any restoration has…

This video is about a convoi which gathers only Yamaha RX-Z on the trip to Mersing Johor. I was amazed by how long the parked RX-Z lined up for the show.Watch the video and see what I meant!

Yamaha RX-Z 135 16T Front Sprocket Yamaha RX-Z 135 39T Rear Sprocket Yamaha RX-Z 135 428 Chain Standard Yamaha RX-Z from factory is fitted with 16T and 46T (if you are wondering what is the “T” behind the number, it is actually TEETH).Currently, I’m using 16T-42T on my Yamaha RX-Z since I use it as…