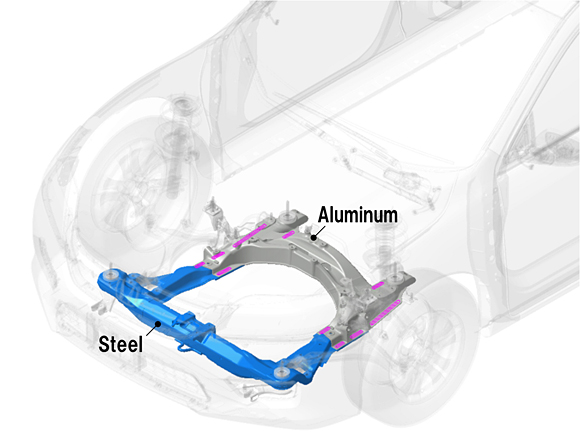

TOKYO, Japan, September 6, 2012 – Honda Motor Co., Ltd. today announced that it has newly developed a technology for the continuous welding of the dissimilar metals of steel and aluminum and applied it for the first time in the world to the subframe of a mass-production vehicle, a key component of a vehicle body frame. Honda will adopt this technology first to the North American version of the all-new 2013 Accord, which will go on sale in the United States on September 19, 2012, and will expand application sequentially to other models.

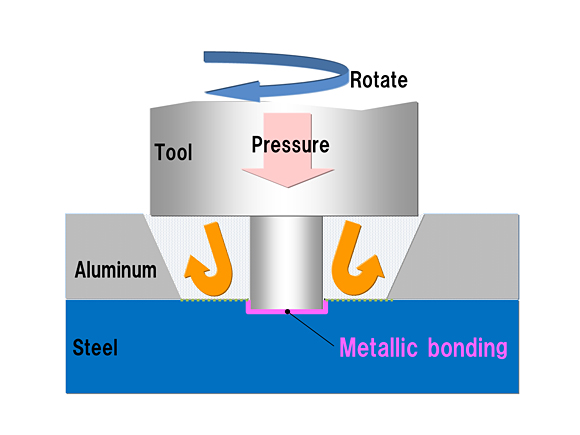

Striving to reduce vehicle weight in order to increase fuel economy, Honda focused on Friction Stir Welding (FSW) and developed a new technology for the continuous welding of steel and aluminum. This technology generates a new and stable metallic bonding between steel and aluminum by moving a rotating tool on the top of the aluminum which is lapped over the steel with high pressure. As a result, the welding strength becomes equal to or beyond conventional Metal Inert Gas (MIG) welding*1.

This new technology contributes to an improvement in fuel economy by reducing body weight by 25% compared to a conventional steel subframe. In addition, electricity consumption during the welding process is reduced by approximately 50%. It also enabled a change in the structure of the subframe and the mounting point of suspension, which increased the rigidity of the mounting point by 20% and also contributed to the vehicle’s dynamic performance.

Furthermore, Honda established a new method to apply this technology to mass-production vehicles. Conventionally, FSW required use of large equipment, but Honda developed a FSW continuous welding system applied to a highly versatile industrial robot. This system also can be used for aluminum-to-aluminum welding and thus, the welding system with the same specifications can be used for production of a full-aluminum subframe.

Honda also developed a non-destructive inspection system*2 using a highly-sensitive infrared camera and laser beam, which enables an in-line inspection of the bonding location for every unit.

- *1

- A welding technique most commonly used for welding of identical materials such as steel-to-steel or aluminum-to-aluminum

- *2

- A system that evaluates quality without actually destructing the parts

Dear lagenda 115zr owner, should i change from 115zr to gt128?need opinion coz i already own 115zr and not satisfied with the performance and fuel consumption compare to last 110cw and 110zr i used.TQ

New technology?

It is called friction welding. Widely used in oil and gas, aerospace and automotive too (mostly large trucks chassis and trailers). Maybe the 1st mass produced car to use this, but calling this tech new and saying it is a new tech that they develop is just bull.

maybe for marketing purpose.